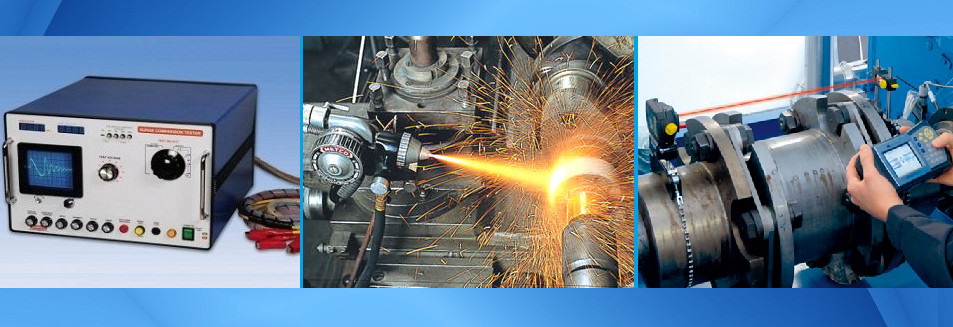

Our Reliability Field Services offer maximum performance at minimal cost. Sudden, unexpected downtime can be reduced dramatically with these cost-effective services:

✓ Electronic Repair

✓ Vibration Analysis

✓ Dynamic Balancing

✓ Shaft Alignment

✓ Motor testing

✓ Metal Spray

✓ Pump Repair

✓ Gear Box Repair

Letrik Kama is your single source for reliability field services. Whether it is simply motor repair or complete motor management, pump, and gear box repair we have the experienced personnel and technology to maintain, test and analyze your assets.

In the event off-site evaluation is required, we will pickup, diagnose, repair and return your equipment. To minimize downtime, we may be able to keep your operation up in the meantime with a unit from our inventory of exchange motors.

Rewinding starts with the original windings being carefully removed by our safe stripping method. This method maintains the integrity of core iron and mechanical characteristics without damage.

Windings are tied down at both ends and electrically tested prior to varnishing. Stators and armatures are varnish by using conventional dip and bake methods.

Recognizing no two repairs are alike, we also have the flexibility to meet a wide variety of customer repair requirements. We carry a full stock of replacement parts, materials, and a complete wire inventory to handle special repairs. Our many capabilities include dynamic balancing, vibration analysis, generator winding, documentation, assembly, and testing.

We offer the following types of test:

1. Surge, HiPot and PI Test

DC Hi-Potential Test: Enables us to examine ground wall insulation that may be damaged due to breakdown or high leakage current.

PI Test: Enables us to examine the gradual deterioration of the insulation and the need for replacement.

Our team will checks to ensure bearings are not defected or worn and mechanical fits are correctly in place.

1. Offset

2. Bevel

3. Planetary

4. Helical

5. Sequential

7. Worm reduction